KRINNER foundation screws, also known as ground screws, allow for quick installation and offer structural capabilities comparable to traditional foundations and piles.

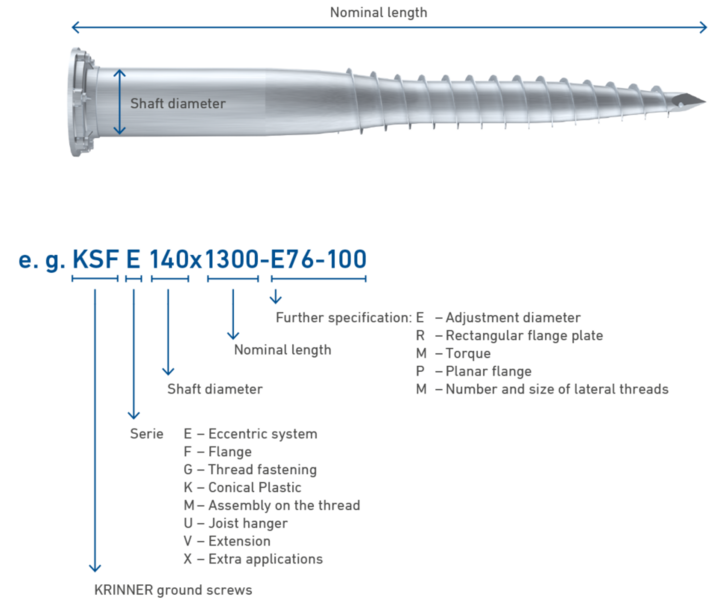

KRINNER Ground Screw Code

Each KRINNER ground screw has a structured product code that indicates its exact specifications:

- Series (KSF, KSF E, etc.) – Defines the screw type (Eccentric system, Flange, Thread fastening, Conical plastic, etc.).

- Shaft diameter (e.g., 140 mm) – The main body diameter of the screw.

- Nominal length (e.g., 1300 mm) – The total length of the screw.

- Further specification (e.g., E76, R, P, M) – Additional details such as adjustment diameter, flange type, torque, or thread design.

- Optional suffix (e.g., -100) – Number and size of lateral threads or other specific features.

This system ensures that each screw can be precisely identified and matched to its application, whether for foundations, extensions, or special constructions.

G Series

The G-series ground screws are equipped with either one, three or four threaded screws. They are ideally suited for the quick, vertical and permanent installation of masts and fence posts, for example. Optionally, the fence posts, for example, can also be quickly and permanently fixed into place with the special granulate.

-

$30.00Nominal length (mm)550Tube diameter (mm)68Weight (k g)1.90Item numberA0403

-

$36.00Nominal length (mm)650Tube diameter (mm)68Weight (k g)2.00Item numberA0405

-

$37.50Nominal length (mm)650Tube diameter (mm)68Weight (k g)2.00Item numberA0406

-

$147.00Nominal length (mm)800Tube diameter (mm)76.10Weight (k g)3.00Item numberA0411

E Series

The E-series ground screws can be optionally equipped with an excentre set depending on the application. The excentre set allows you to make precise adjustments and ensures a perfect, vertical positioning of the object that you want to install. The system is particularly suitable for the resonance and vibration dampening installation of poles and masts for example.

-

$537.00Nominal length (mm)1,600Tube diameter (mm)139.70Weight (kg)18.50Item numberA0382

-

$477.00Nominal length (mm)1,300Tube diameter (mm)139.70Weight (kg)15Item numberA0380

F Series

The F-series ground screws are equipped with round or square flanges. The fixation of the bearing object made possible by this ensures the highest possible stability and safety, even with large or extreme structural loads.

-

$195.00Nominal length (mm)800Tube diameter (mm)76.10Weight (kg)4.50Item numberA0390

-

$237.00Nominal length (mm)1,000Tube diameter (mm)76.10Weight (kg)6Item numberA0388

-

$267.00Nominal length (mm)1,300Tube diameter (mm)76.10Weight (kg)7.50Item numberA0389

-

$282.00Nominal length (mm)1,600Tube diameter (mm)76.10Weight (kg)12Item numberA0393

M Series

The M-series ground screws have a centred M-thread which allows the object that is to be carried to be directly screwed onto the ground screw. They are particularly suitable for constructing prefabricated garages and containers, for example.

-

$159.00Nominal length (mm)800Tube diameter (mm)76.10Weight (kg)4.20Item numberA0436

-

$192.00Nominal length (mm)1,000Tube diameter (mm)76.10Weight (kg)5.30Item numberA0434

-

$207.00Nominal length (mm)1,300Tube diameter (mm)76.10Weight (kg)7Item numberA0435

-

$267.00Nominal length (mm)1,300Tube diameter (mm)76.10Weight (kg)10Item numberA0443

V Series

Our V-series ground screws are extendable. The ground screws can be extended according to the project requirements and were specially developed for projects with high loads. The products V89, V114 and V140 come with DIBt-approval.

-

$117.00Nominal length (mm)860Tube diameter (mm)76Weight (kg)5Item numberA0503

-

$147.00Nominal length (mm)300Tube diameter (mm)76Weight (kg)4Item numberA0502

-

$162.00Nominal length (mm)860Tube diameter (mm)89Weight (kg)10Item numberA0516

-

$171.00Nominal length (mm)1,500Tube diameter (mm)76Weight (kg)10Item numberA0496

U Series

The U-series ground screws have been specially designed for all regularly-dimensioned timber beams. They are perfect for the simple and fast mounting of horizontal and vertical timber beams, for example during carport and wooden terrace construction.

-

$36.00Nominal length (mm)550Tube diameter (mm)60Weight (k g)2.40Item numberA0456

-

$48.00Nominal length (mm)730Tube diameter (mm)60Weight (k g)2.80Item numberA0459

-

$48.00Nominal length (mm)730Tube diameter (mm)60Weight (k g)2.70Item numberA0458

-

$54.00Nominal length (mm)730Tube diameter (mm)60Weight (k g)2.90Item numberA0457

You can apply it in many places

One solution for many areas: construction, roads, fences and leisure.

Ecological

Efficient

Secure

Frequently asked questions

Ground screws are made from steel and are mostly galvanised components for foundation construction. They are driven into the ground either manually or with a ground screw driver. During the driving in, the surrounding soil is pushed to the sides and compressed. This is how the ground screw is stabilised and can bear the same loads as conventional concrete foundations.

Ground screws only work as foundations after they have been driven into the ground. For this reason, the soil composition is a crucial factor when it comes to ensuring the stability of the foundations. Our products can be used in almost all types of substrate, even in rock. However, a pre-drilled hole is needed here. Our products cannot be used in aggressive or contaminated soils. A geological survey (soil survey) can give an insight into the soil composition and the load-bearing capacity of the substrate. This must be consulted during the foundation planning. Chemical soil analyses, which are often part of the geological survey, provide important data about the aggressiveness of the soil.